【 New Product release 】 Large model blessing, 5 minutes configuration! DexForce Intelligence launched industrial logistics pure visual imaging sensing suite

Large model enabling, breaking through hardware limitations, DexForce intelligence launched the first new IRIS smart camera and industrial logistics pure visual imaging perception kit, working with partners to promote new quality production capacity to a new era of efficiency.

01 IRIS + Large Model > Traditional 3D solution

In modern supply chain management, as a key link of logistics and manufacturing process, the efficiency of unstacking is crucial to the smooth operation of the entire supply chain. At present, the use of “3D vision + robot” instead of manual depalletizing, so as to improve production efficiency, improve quality and consistency, reduce labor risks, and reduce operating costs has gradually become the industry consensus. And how to make 3D visual depalletizing more common, easier to use and more efficient in various fields through highly versatile technology is one of the breakthrough directions of cross-dimensional intelligence in the field of logistics and manufacturing.

Cross-dimensional intelligence combined with its own technology accumulation in the aspects of physical intelligence, large model, 3D vision and application experience in many terminal industries, officially released the first domestic IRIS smart camera, and launched a new upgraded pure visual imaging perception kit for the unstacking scene, committed to making 3D visual guidance applications “higher, faster, stronger and easier to use”. The new kit can cover more comprehensive scenes, effectively cope with direct sunlight or semi-outdoor environments, with more universal recognition capabilities, while completing visual configuration in as little as 5 minutes.

02 Breaking the limits of 3D imaging technology - IRIS smart camera combining AI imaging and binocular structure

Common 3D industrial cameras mainly use structured light, time of flight (TOF) and other technologies to obtain the shape and position information of objects in three-dimensional space, so as to complete downstream detection, positioning, measurement and other tasks. However, these technologies also have many limitations, such as imaging susceptibility to ambient light, slow imaging times, short camera life, and relatively high costs.

In view of the limitations of the above 3D imaging technology, cross-dimensional intelligence based on DexVerse™ data and the intelligent simulation engine, through the innovative development of Sim2Real application in binocular stereoscopic imaging, successfully broke through the technical limitations of traditional 3D imaging, and innovatively launched IRIS intelligent camera based on binocular stereoscopic imaging technology. Binocular stereo imaging technology mimics the principle of human binocular vision, using two cameras to obtain images from different angles, and through the intelligent algorithm trained by Sim2Real, using two sets of images from different angles, it can accurately reconstruct the three-dimensional point cloud of the scene within 0.5s at the fastest under various ambient light, solving the problem of traditional 3D cameras. Effectively improve the stability of the vision system, bringing revolutionary innovations and breakthroughs to the field of 3D imaging.

In customer project sites in direct sunlight or semi-outdoor environments, traditional 3D imaging technology is difficult to meet the needs of user scenes due to the limitation of ambient light interference and complex lighting conditions. The IRIS camera based on binocular stereo imaging is adopted in the cross-dimensional intelligence, which not only effectively solves the imaging problem under complex lighting and semi-outdoor strong light conditions, but also improves the stability and accuracy of the system. More importantly, binocular imaging technology has achieved cost optimization while maintaining high performance, highlighting its excellent economic advantages.

03 New quality efficiency booster for depalletizing -- industrial logistics pure visual imaging perception kit

For the unstacking scene, DexForce intelligence based on long-term accumulation on the embodied intelligent multi-modal large model, combined with IRIS smart camera, to create a new industrial logistics pure visual imaging perception kit based on 3D VLA (3D Vision Language Action) large model. Support for de-stacking scenarios approaches the realization of AnyGrasp, instead of customized data calibration and task programming for different operating objects. With stronger core capabilities, higher versatility, faster delivery, and better application costs.

More powerful core capabilities: easily cope with different textures, materials of cardboard boxes and sacks positioning

- Gunny bag positioning: accurate positioning of various materials, textures of gunny bags

- Carton positioning: accurate positioning of cartons of various materials and textures

- Base positioning: accurately locate the base underneath the carton (if any)

- Carton size measurement: accurately measure the length and width of the carton

- Base size measurement: accurately measure the length and width of base

- Carton length and width direction recognition: accurately identify the direction of the long side and short side of the carton

Higher versatility: Support adaptive learning, general recognition of various depalletizing material 3D visual large model

With Sim2Real as the core, DexForce Intelligence has created a unique DexVerse™ data and embodied intelligence simulation engine for data generation and large model training. In the depalletization scene, DexVerse™ can simulate the depalletization scene of cartons and bags, generate massive high-quality data with accurate labeling information, and use Sim2Real to train the visual large model for the depalletization scene. At the same time, through a large number of ground projects, the accumulation of real data, the use of Sim2Real mask mode can be fine-adjusted on the side, and the use of Real2Sim shadow mode end-to-side domain self-adaptation, continuous training and improvement of model capabilities, providing a general recognition of various depalletising materials 3D visual model.

When the cross-dimensional intelligent vision large model is deployed, the model parameters can be fine-tuned based on the predicted results, so as to further improve the performance of the model. At the same time, for different real scenes, 3D vision large models can be combined with special textures in a few real scenes to automatically generate high-quality simulation data for special textures, and then fine-tune the model, so as to overcome the impact of complex, special and ambiguous textures on the model performance, such as the reflection of sacks, folds and collapses. Difficult problems such as tight fitting of cartons and adhesive tape on the surface of customer projects are approaching the realization of AnyGrasp in the depalletizing scenario

Faster delivery: Zero code, up to 5 minutes

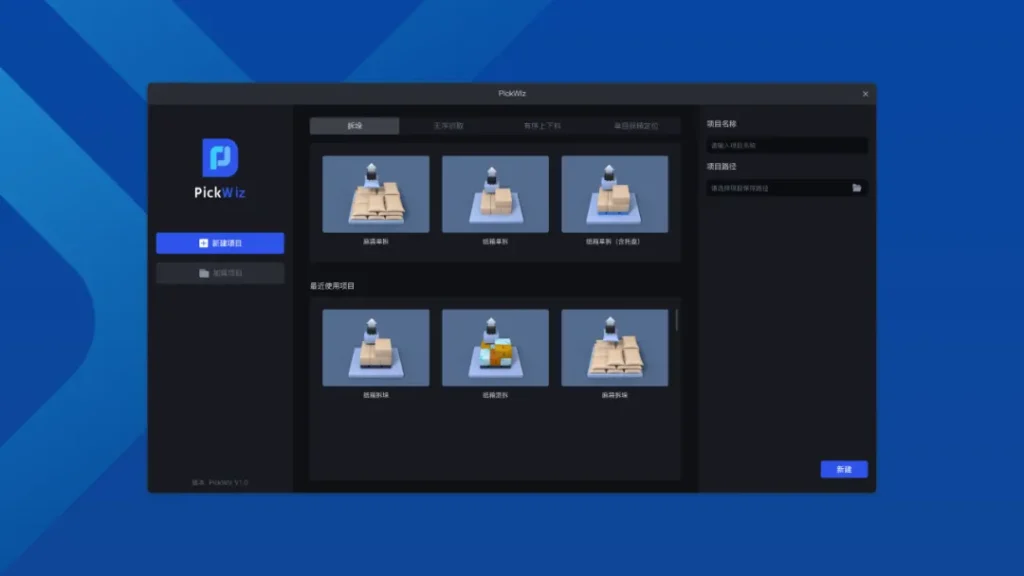

In order to improve the efficiency of on-site delivery, cross-dimensional Intelligence upgraded the 3D visual guidance software PickWiz, effectively reducing the learning threshold of 3D visual guidance grasp software and significantly shortening the delivery cycle. Adhering to the design concept of zero code, PickWiz provides different preset options for different task scenarios based on the accumulated experience of integrating embodied intelligence related technologies and industries, so that users can flexibly match and directly invoke the visual configuration preset by the software in the scene and the corresponding 3D visual large model based on the actual situation.

At the same time, PickWiz offers a variety of commonly used robot presets for users to quickly complete calibration and grasping tasks. Expand more application scenarios and greatly shorten the debugging time, the fastest 5 minutes to complete the visual configuration, 20 minutes to cooperate with the robot to grasp and debug.

Better application cost: High versatility, ease of use to support scale, fast delivery

Unlike traditional 3D vision guidance solutions, which are frequently customized by projects, bringing long delivery cycles and high application costs, cross-dimensional intelligence’s new pure visual imaging perception suite, with its excellent versatility and ease of use, can support large-scale applications and rapid delivery, and achieve a more extreme application cost optimization on the basis of maintaining higher performance. At the same time, during the official launch of the new product, you can enjoy the new product limited time preferential policies, helping customers and partners to “cross the dimension, faster step”.

04 Application Cases

The 3D visual imaging perception suite launched by DexForce Intelligence has completed landing and stable operation in multiple customer sites in logistics, chemical, agriculture, food and other industries.

These cases show the technical strength and wide application potential of the DexForce intelligent 3D vision imaging perception suite, and I believe that through this new upgrade iteration, cross-dimensional intelligence will work with more partners to create more convenience and value for various industries.